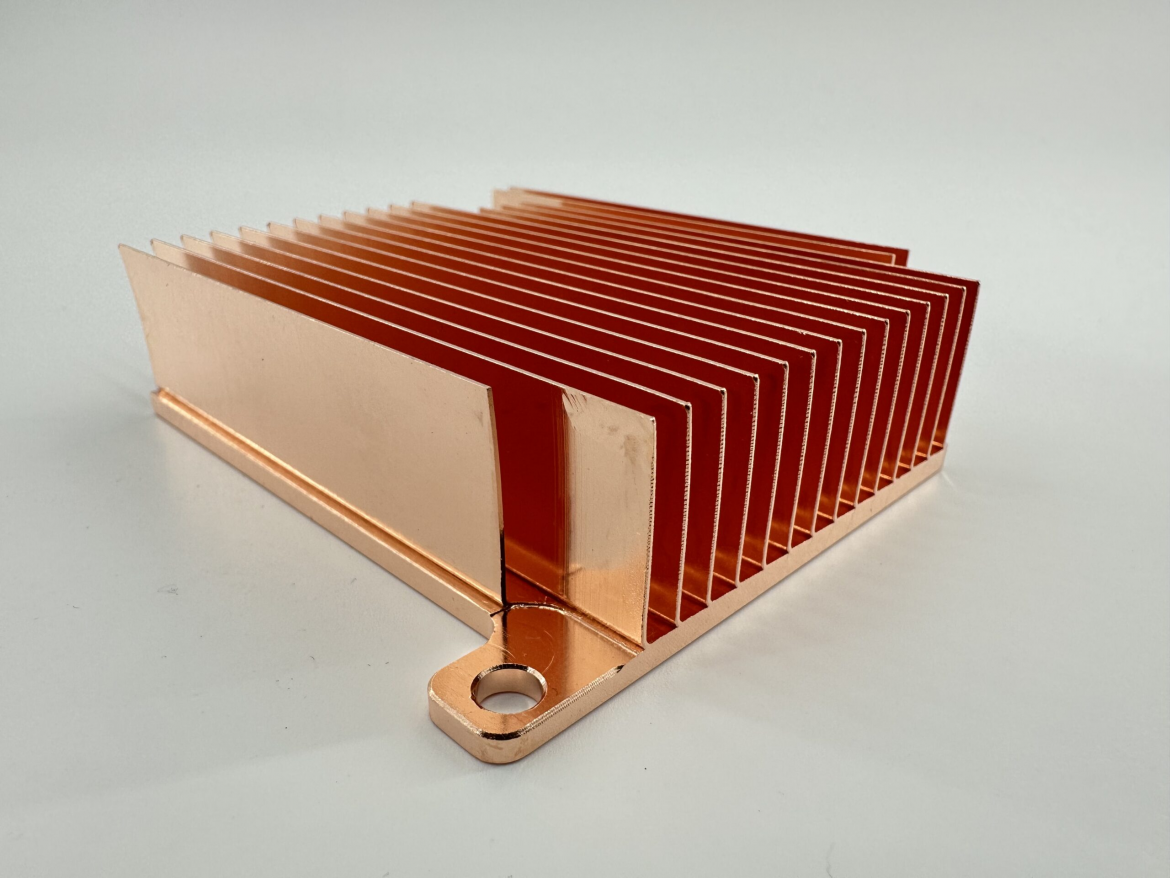

Engineers evaluating thermal solutions often begin by comparing how copper and aluminum behave in a skived heatsink design. A skived heatsink is produced by removing thin, high-density fins directly from a single metal block using a controlled skiving process. This one-piece structure eliminates solder joints and minimizes thermal resistance between the base and fins, making the architecture suitable for devices that experience concentrated heat sources. Companies such as Dingmetal provide both copper and aluminum formats, giving procurement teams and R&D engineers flexibility when considering thermal goals, mechanical restrictions, and long-term reliability expectations. As devices grow more compact, the relationship between material conductivity and surface area becomes increasingly relevant, especially when selecting cooling hardware for industrial controllers, power equipment, or communication systems.

Differences in Thermal Conductivity, Mass, and Structural Behavior

Copper versions of skived heat sinks offer higher thermal conductivity, allowing heat to spread efficiently from the base into the uniformly spaced fins. This behavior is important in high-density electronic assemblies, where power modules, processors, and switching components generate continuous thermal loads. Because the fins and base remain part of a single copper block, temperature transfer remains stable even under fluctuating operating conditions. Aluminum skived heat sinks, meanwhile, provide moderate conductivity but offer meaningful advantages in weight-sensitive applications. Their reduced mass can lessen mechanical stress on mounting brackets or housing structures, which is relevant for handheld tools, compact communication terminals, or systems where vibration is expected. When engineers compare the two materials, they often balance conductivity, structural behavior, and allowable mass before selecting a configuration that aligns with system-level requirements. Teams working with Dingmetal commonly assess prototypes of both metals when a project demands precise temperature management without exceeding mechanical limitations.

Application Suitability and Practical Manufacturing Considerations

The manufacturing characteristics of each metal also influence how a skived heatsink performs. Copper allows extremely dense fin structures, resulting in a large effective surface area that supports rapid heat dissipation when airflow is limited. Aluminum fins can also be closely spaced, and the lower mass of aluminum helps streamline installation in assemblies where overall weight must remain controlled. Many engineers specify aluminum units for LED drivers, compact power supplies, and general electronic modules, while copper configurations often fit industrial automation equipment, high-power computing boards, and thermal control units with minimal space but high heat flux. Regardless of the material choice, Dingmetal produces these units using a consistent skiving process, ensuring uniformity across fins and steady performance during extended operation. Understanding these manufacturing aspects helps decision-makers align cooling hardware with project expectations without relying on assumptions or marketing claims.

Conclusion: Choosing the Right Material for Reliable Thermal Management

Selecting between copper and aluminum skived heat sinks depends on your device’s heat load, available space, airflow conditions, and mechanical constraints. Copper models deliver stronger heat-spreading capability, while aluminum versions provide balanced performance with lower mass. In both materials, the precision skiving process forms thin, consistent fins directly from a solid block, enhancing surface area and reducing thermal resistance. By comparing these characteristics, engineering teams can identify whether conductivity, weight, or structural behavior should guide their cooling strategy. With support from Dingmetal, users can choose a skived heatsink configuration that aligns with long-term stability and practical thermal control needs across a range of industrial applications.