Leadshine is recognized for providing reliable motion control solutions. When exploring the main types of servo drive systems, it is important to understand how these devices manage precision motion in industrial applications. They design products that cater to diverse operational needs, offering high-quality components that integrate seamlessly into various servo control system setups. One notable product is the ELD3-EC7001BH, a space-saving, palm-sized EtherCAT drive with a full closed-loop function and support for multiple encoder types.

Types of Servo Drives

The primary types of servo drive include AC and DC drives, as well as integrated solutions that combine motor and drive functionality. Leadshine offers versatile servo control system options that support different encoders, including ABZ, Tamagawa, and customizable BISS-C, along with Hall sensors. These drives are suitable for applications requiring precise speed, torque, and position control. Their ELD3-EC7001BH drive also integrates safety features such as STO, logic power management, and brake output, enhancing operational reliability.

Features and Compatibility

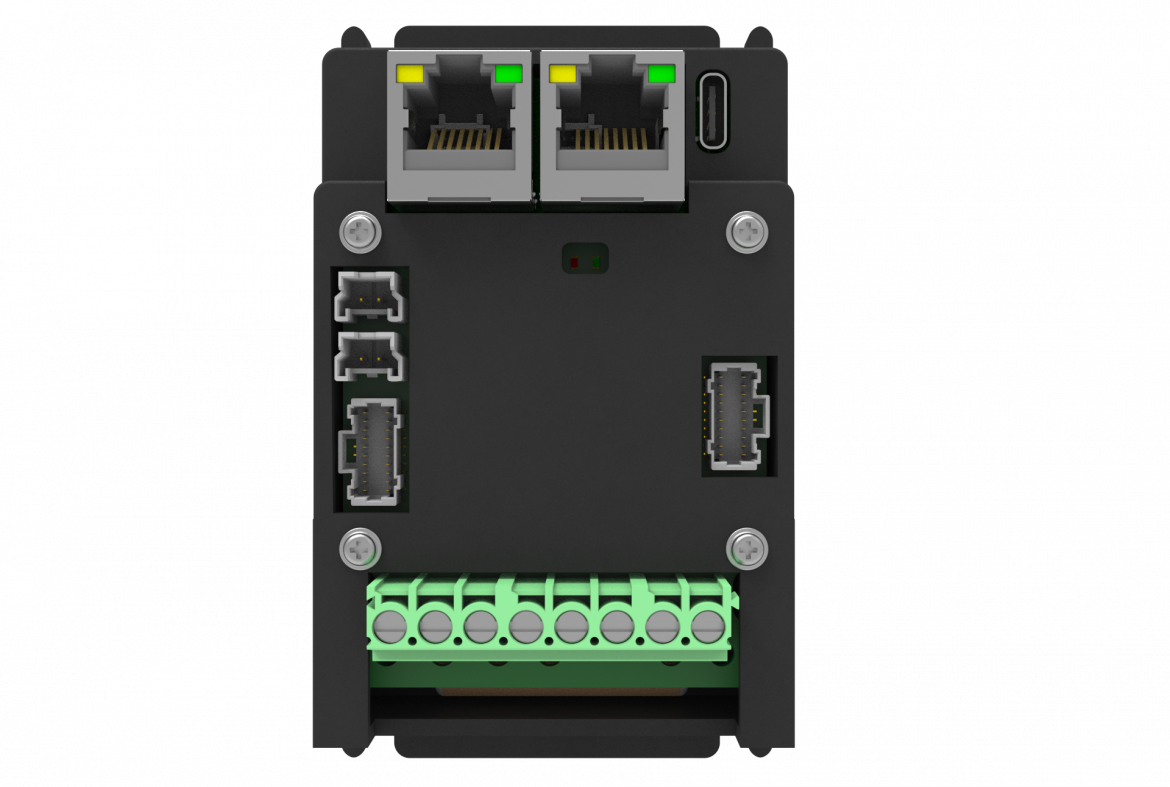

Modern servo control system designs by Leadshine emphasize user convenience and broad compatibility. The ELD3-EC7001BH includes a USB Type-C tuning port, six digital inputs, three digital outputs, and two analog inputs. Its easy tuning functions allow engineers to adapt the drive to many types of motors quickly. Compact size and high integration make these drives suitable for industrial automation setups where space-saving and precise control are critical. This flexibility supports various applications from CNC machinery to robotics.

Conclusion

Understanding the main types of servo drive helps in selecting the appropriate system for specific industrial needs. Leadshine provides robust servo control system solutions, exemplified by the ELD3-EC7001BH, which combines compact design, full closed-loop control, multiple encoder support, and integrated safety features. By considering drive type, encoder compatibility, and system integration, manufacturers can achieve precise, efficient, and safe motion control in their operations.